What to do if your crystal oscillator isn't oscillating?

When a crystal oscillator, the key to providing a stable clock signal, unexpectedly stops oscillating, R&D and production progress are immediately challenged.

Don't panic!

As a professional crystal oscillator manufacturer, YXC Xiaoyang offers a systematic, accurate, and efficient "three-step troubleshooting method." Following a logical progression from the outside in, from easy to difficult, we'll help you quickly narrow down your troubleshooting scope and pinpoint the cause of the problem.

1. From the Outside in: Preliminary Inspection of Appearance and Manufacturing Process

Before performing any destructive operations, please perform a "detective" inspection to identify any external issues visible to the naked eye or detectable with simple tools:

Visual Inspection (Secure the Site):

① Crystal Oscillator Body

Inspect the housing for mechanical damage such as sagging, impact marks, or cracked base.

② Soldering Condition: Inspect the pins for obvious cold solder joints, solder joints, or solder joints on edge pins.

③ PCB Condition: Inspect the PCB traces surrounding the crystal for visible breaks, burns, or other signs of damage.

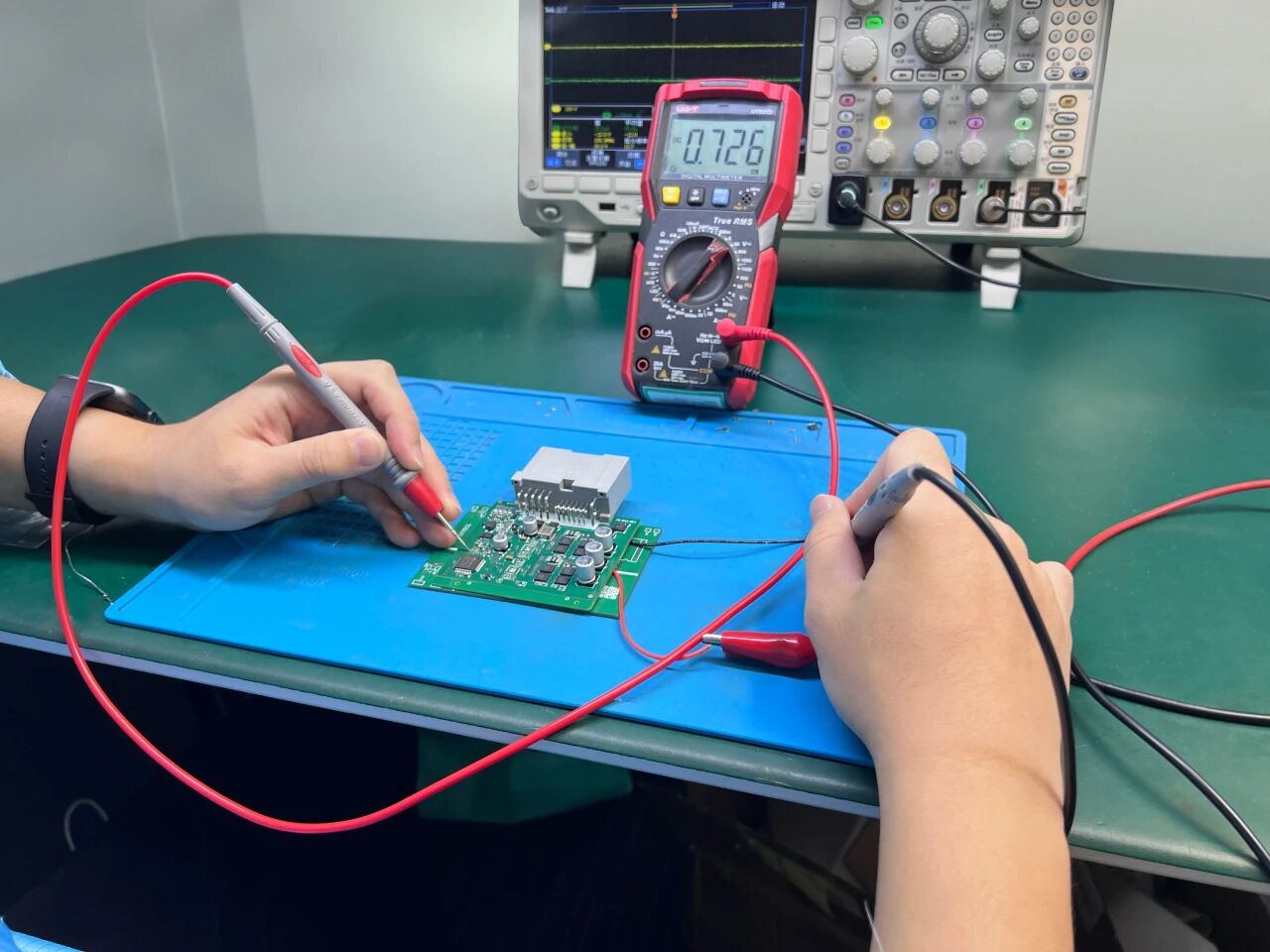

Circuit Electrical Inspection (Multimeter)

① Continuity: Use the multimeter's beep setting to check for open solder joints, shorts, or opens.

② Power Supply Check (Active Crystal Oscillator): Use the multimeter's voltage setting to measure the correct supply voltage (VDD) on the crystal's power supply pins.

2、Measurement Analysis: Driver Analysis and Troubleshooting

After eliminating process and circuit connectivity issues, we proceed to determine driver conditions and troubleshoot hidden damage:

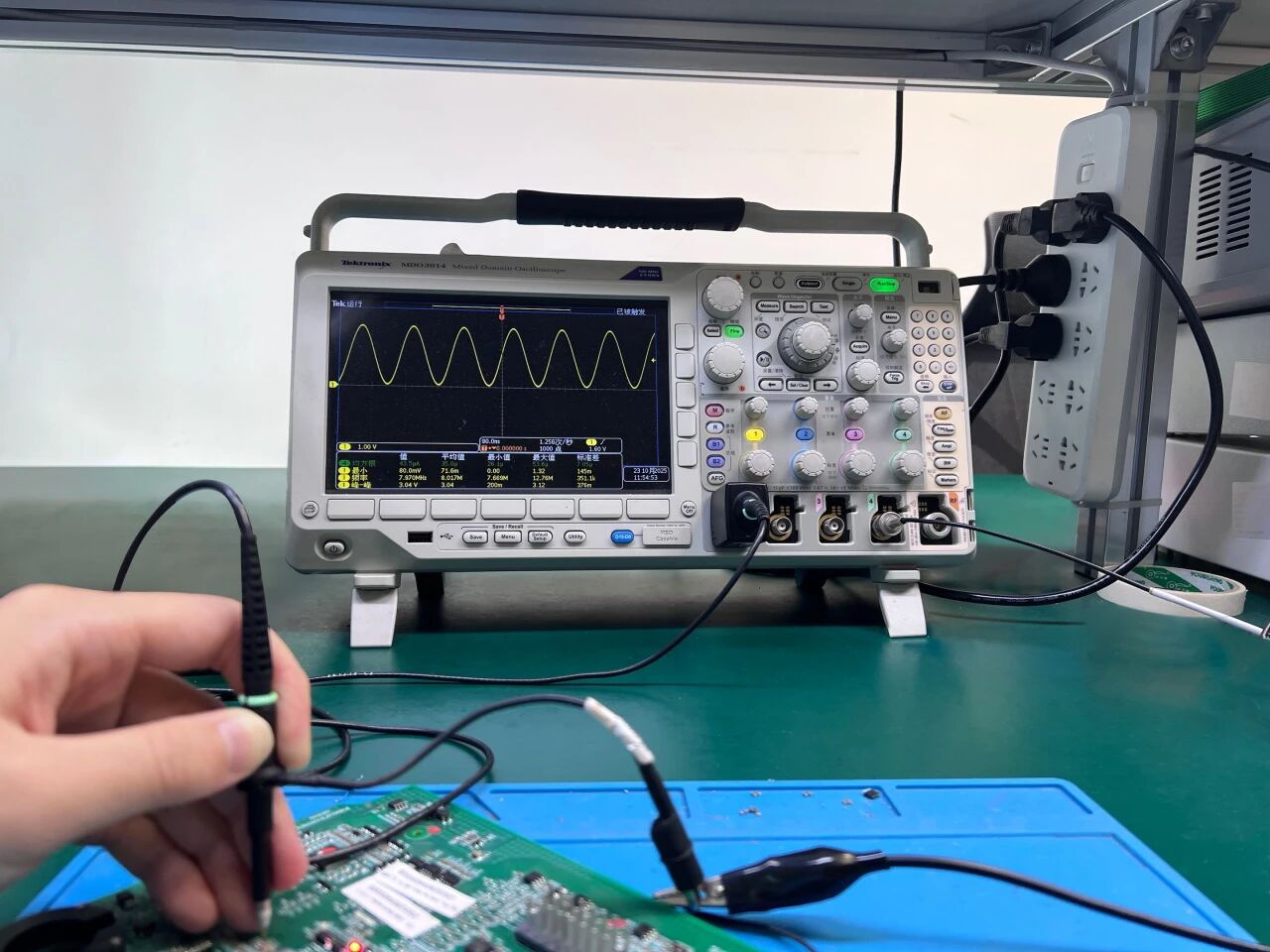

01 Confirm Oscillation Status

· Passive Crystal Oscillator

Use an oscilloscope to connect to the output pin and measure VPP (peak-to-peak), or connect to a frequency counter/spectrum analyzer to confirm frequency output.

· Active Crystal Oscillator

Directly measure whether the output terminal produces a stable square wave.

02 Key Parameter Matching

Load Capacitance (Passive Crystal Oscillator)

Have the external matching capacitors (C1, C2) of the passive crystal oscillator been calculated and adjusted to ensure that the actual load capacitance seen by the crystal in the circuit matches the load capacitance (CL) specified in the datasheet?

CL = CS + (C1 x C2) / (C1 + C2)

Note: CS stands for stray capacitance, which refers to stray capacitance within the IC, parasitic capacitance between layout traces, and parasitic capacitance between PCB layers.

Matching errors are a common cause of non-oscillation or significant frequency deviation.

03 Process Risk Check

· Thermal Stress Damage

Confirm whether there is a risk of high-temperature soldering. Check whether the peak reflow temperature or soldering time exceeds the recommended values in the crystal oscillator's datasheet.

Excessive thermal stress may increase the crystal's internal equivalent series resistance (Rs), directly leading to difficulty starting or failure.

· Mechanical stress damage

Check whether the crystal oscillator has been exposed to ultrasonic cleaning, ultrasonic welding, or high mechanical stress environments.

Resonant environments can easily cause the crystal to break.

3、Cross-verification: Identifying the Fault Source

If no obvious abnormalities are found in the first two steps, or if a performance issue with the crystal oscillator itself is suspected, conduct cross-verification:

Replace the crystal oscillator with a good, in-stock crystal from the same batch or model.

①If the replacement returns to normal operation, it can be preliminarily determined that the crystal oscillator itself is defective. Please retain the defective sample and contact the crystal oscillator manufacturer for return testing.

②If the problem persists after replacement, it may indicate a potential abnormality in the external oscillator circuit (such as insufficient negative impedance or improper matching), the oscillator drive pins of the main control chip, or other abnormalities.

Using the above "three-step locating method,"

you can effectively narrow down the scope of investigation and independently resolve some non-oscillation issues.

Need further technical support?

Ultimate Guarantee!

Professional questions, leave them to the professionals at YXC!

YXC Yangxing Technology has a professional crystal oscillator laboratory and a team of experienced FAEs, providing you with solid support:

1. Crystal Failure Analysis

We provide professional failure analysis using precision equipment to help you pinpoint the cause of the failure and issue an authoritative report.

2. Oscillator Circuit Optimization Recommendations

We provide professional optimization solutions for negative impedance, drive level, and other issues related to your external circuit.

3. Full-Process Technical Support

From design selection to mass production, we ensure your clock source is stable and reliable.