Temperature-controlled and temperature-compensated crystal oscillators are commonly used in circuit boards. Both temperature-controlled and temperature-compensated crystal oscillators are crystal oscillators with active crystal oscillators, so the oscillator circuits they form require a power supply to operate.

Xiao Yang briefly explains the difference between temperature-compensated and temperature-controlled crystal oscillators:

> Definition:

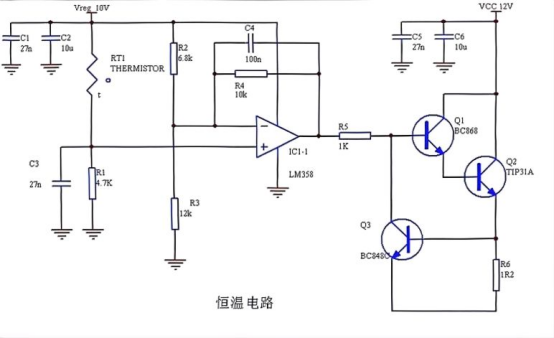

An oven-controlled crystal oscillator (OCXO) uses a constant temperature chamber to maintain a constant temperature of the quartz crystal resonator, minimizing the frequency variation of the oscillator's output caused by ambient temperature fluctuations. An OCXO consists of an oven control circuit and an oscillator circuit. Temperature control is typically achieved using a differential series amplifier constructed with a thermistor "bridge."

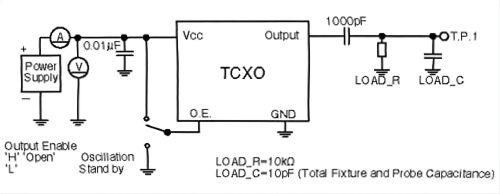

A temperature-compensated crystal oscillator (TCXO) uses internal electronic (analog or digital) compensation to reduce the frequency-temperature drift of the crystal element. A temperature-compensated crystal oscillator (TCO) uses the temperature-dependent changes in the crystal's load reactance to compensate for the crystal's frequency temperature stability.

The term "TCO" comes from a compensation method used in quartz crystal oscillators to achieve the precision required for product applications. A TCO is defined as a quartz crystal oscillator that uses a peripheral circuit to reverse the inherent physical properties of a piezoelectric quartz crystal (the frequency changes with temperature in a cubic curve due to the piezoelectric effect) to minimize the change in the crystal's original frequency with temperature.

> Operating Principle:

Oven-controlled crystal oscillators utilize a constant temperature chamber to maintain the temperature of the crystal oscillator or quartz crystal resonator, minimizing the frequency variation of the oscillator caused by ambient temperature fluctuations. Since the oscillation frequency of a crystal oscillator varies with temperature, the crystal oscillator is controlled at a constant temperature to maintain frequency stability and improve its phase-frequency characteristics.

TCOs use an additional temperature compensation circuit to minimize the frequency variation caused by ambient temperature changes. Temperature compensation works by varying the load capacitance in the oscillation circuit so that it changes with temperature, thereby compensating for the frequency drift of the resonator caused by ambient temperature fluctuations. Since the oscillation frequency of a crystal oscillator varies with temperature, the resonant capacitance of the crystal is controlled to change with temperature to offset the effect of temperature on the crystal frequency, thereby improving frequency stability.

> Measurement Accuracy:

Generally, oven-controlled crystal oscillators (OCXOs) have frequency stability that is more than two orders of magnitude higher than temperature-compensated crystal oscillators (TCCs). For example, the frequency stability of a temperature-compensated crystal oscillator (TCXO) is typically between 10⁻¹ and 10⁻7, while an oven-controlled crystal oscillator (OCXO) can achieve 10⁻8 to 10⁻¹⁰ or even higher. Therefore, oven-controlled crystal oscillators are commonly used in high-end measuring instruments such as frequency meters, signal generators, and network analyzers.

TCCs also offer better startup characteristics. Because OCCs require a warm-up period, their frequency stability takes several minutes to reach nominal specifications, and achieving optimal long-term stability requires even longer operation time. Therefore, oven controlled crystal oscillators are not suitable for devices that need to work immediately.