When selecting and matching a design, there can occasionally be some hiccups. What load capacitance will allow for oscillation, and what capacitance value is required for fast oscillation response?

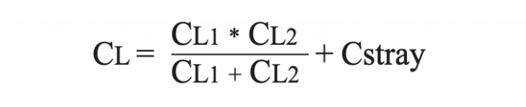

Matching capacitance isn't an absolute or fixed value. For passive crystal oscillators, it's generally best to use two identical capacitors. Commonly used capacitances in many designs include 12pF, 15pF, 22pF, and 33pF, all roughly in the 20pF range.

Quartz crystals cannot be used in RC sine wave oscillation circuits. Because the crystal impedance approaches zero when the quartz crystal is at series resonance, adjusting capacitor C so that the resonant frequency of the LC parallel circuit approaches the natural resonant frequency of the quartz crystal will produce stable oscillation. Therefore, quartz crystals cannot be used in RC sine wave oscillation circuits.

When matching a passive crystal oscillator circuit, two common problems often arise:

1. Non-oscillation: Under-excitation of the crystal oscillator occurs due to insufficient excitation power or excessive start-up time. This phenomenon typically manifests as the crystal oscillator failing to operate after a power-on reset or in low-power mode. The solution is to select a crystal with low power consumption and reduce the external capacitance within the datasheet's allowable range to shorten the start-up time. The capacitance values should be different.

2. High frequency: An oscilloscope can show that the peaks and valleys of the output waveform are flattened. This indicates the crystal oscillator is being overdriven. Resistors should be connected in series with the relevant pins of the chip to adjust the output waveform until the waveform is clear and complete.

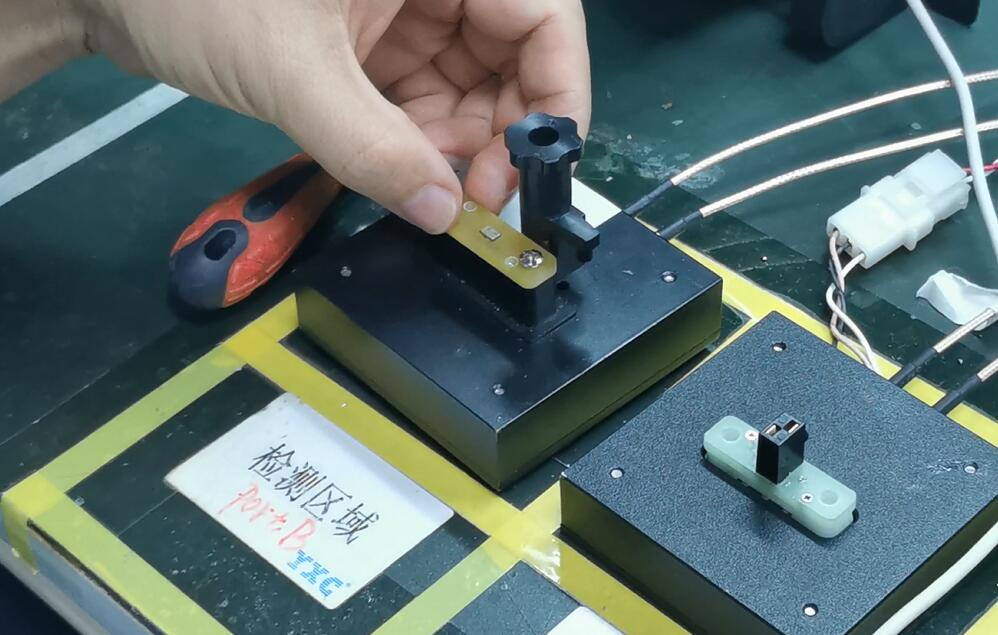

Also, care must be taken during soldering. Improper soldering can damage the crystal oscillator. In severe cases, it can cause it to stop oscillating, or even cause soft damage, allowing the crystal to continue operating normally but suddenly stop oscillating later. Soldering can be done manually or by machine. For manual soldering, the soldering iron tip temperature should be controlled at 350°C/3s or 260°C/5s. Machine soldering can be done by wave soldering or reflow soldering.

For more information on crystal oscillator technology and crystal matching issues, please contact Yangxing's official customer service.