Acceleration sensitivity is the inherent sensitivity of a crystal oscillator to external forces applied in any direction. Quartz oscillators literally provide the heartbeat of the electronic devices we all rely on every day. The useful thing about quartz is that if a voltage is applied, the quartz will begin to vibrate. The downside is that if vibrations are applied, the quartz will generate a voltage. This voltage shows up as phase noise and is a real drag.

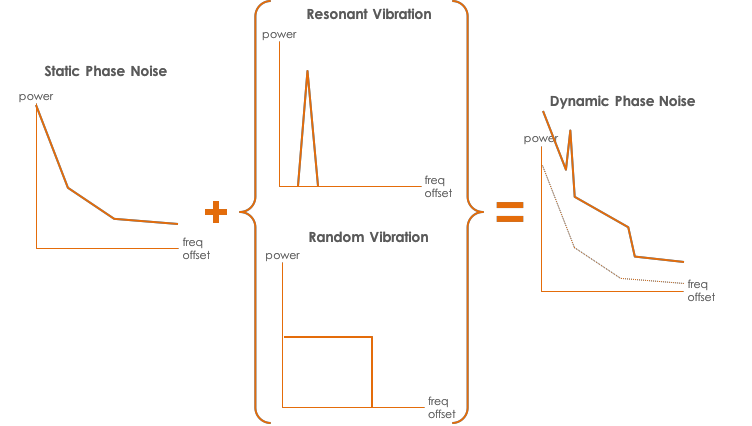

The magnitude of the phase noise, or frequency change, is proportional to the force or acceleration applied. The greater the force, the greater the frequency instability and the greater the noise. Frequency instability due to the acceleration sensitivity of the crystal can affect many aspects of the oscillator's performance, such as: short-term stability and phase noise performance. Phase noise caused by vibrations such as phase jitter can affect the performance of digital communication systems and RF systems. This error will manifest as an increase in bit error rates. All quartz crystals exhibit some degree of inherent vibration sensitivity. So the question remains. What to do? There are many solutions to minimize the impact of acceleration sensitivity on customer systems.

1. Correctly select the resonator

Properly select the resonator (for example: the type of crystal cut used):

The cut of the crystal can have a large impact on the performance of the entire system. AT cut crystals are widely used in many types of reference clocks. Studies have shown that the performance of AT cut crystals is almost the same as that of SC cut crystals. However, the overall gamma vector of SC cut crystals is still much better than that of AT cut crystals.

The crystal mounting structure also plays an important role in the performance of the crystal under vibration. There are a variety of crystal packages with different mounting structures, however, in our experience, different pin packages with a four-point mounting structure have been found to have the highest level of vibration resistance.

By fixing the crystal in 4 positions, the mounting resonance of the package can be greatly changed, thereby reducing the overall impact of vibration on performance.

After selecting the right crystal, the performance can be further guaranteed by screening for acceleration sensitivity on all axes. By pre-screening the crystal before mounting into the oscillator package, the customer's cost can be reduced and a custom solution can be provided in a standard package.

2. Perform vibration screening

Perform vibration screening at the resonator level (screening for optimal g sensitivity):

At Bliley, screening is performed by inducing a sinusoidal or random force of known magnitude. The degradation is then measured using a phase noise analyzer. If a sinusoidal waveform of a given frequency is used, the spurs caused by a single tone will be measured. From this data, the acceleration sensitivity of the resonator can be calculated.

If a random spectrum is applied to the crystal, the phase noise over the entire vibration bandwidth can be measured essentially, and the g-sensitivity can be calculated from the given PSD.

3. Passive Isolation

Passive isolation (mechanical damping) can have a profound effect on the acceleration sensitivity of the reference clock. If the input vibration is reduced, the attenuation will also be reduced. Passive isolation does have its disadvantages, and the system can become quite large depending on what is being isolated.

The resonant frequency of the platform can also be a big problem. A typical mount can have a transmissivity of 3.5 to 4, which means that the forces input into the system are amplified. Care should be taken not to exceed the maximum displacement of the system, otherwise the isolator will be damaged.

This problem uses a low natural frequency isolation scheme. In theory, an isolation structure below 1 Hz is ideal, but in practice, these systems are very large due to the need for damping mechanisms and wiggle room, which is where electronic compensation comes in.

4. Electronic compensation

By employing electronic compensation, the size of the passive isolation system can be minimized while still gaining the benefits of a passive installation. Electronic compensation will also minimize the effects of the resonant frequency of the isolation structure.

Electronic compensation provides superior results and can achieve vibration insensitivity levels that are two orders of magnitude less than standard crystals.

The typical compensation scheme used can cover vibrations to approximately 500Hz, while the isolation structure begins to attenuate at approximately 120Hz.

Such a wide crossover range is able to greatly improve the performance of the crystal and essentially provide customers with a vibration-resistant reference signal.